en

-

Products

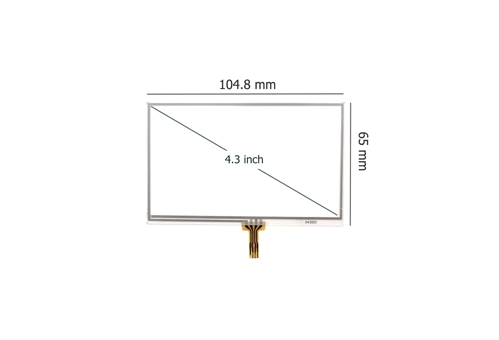

Resistive Touch UART LCD DisplayW0154U2424-R 1.54 Inch Resistive Touch UART LCD Display W0154U2424M-R 1.54 Inch Resistive Touch UART LCD Display W024U2432-R 2.4 Inch Resistance Touch UART LCD Display W024U2432M-R 2.4 Inch Resistance Touch UART LCD Display W024U2432-5-R 2.4 Inch Resistance Touch UART LCD Display W024U2432M-5-R 2.4 Inch Resistance Touch UART LCD Display W028U2432-R 2.8 Inch Resistive Touch Uart LCD Display W028U2432M-R 2.8 Inch Resistive Touch Uart LCD Display W028U2432-5-R 2.8 Inch Resistive Touch Uart LCD Display W028U2432M-5-R 2.8 Inch Resistive Touch Uart LCD Display W032U2432-R 3.2 Inch Resistive Touch Uart LCD Display W032U2432M-R 3.2 Inch Resistive Touch Uart LCD Display W032U2432-5-R 3.2 Inch Resistive Touch Uart LCD Display W032U2432M-5-R 3.2 Inch Resistive Touch Uart LCD Display W035U3248-R 3.5 Inch Resistive Touch Uart LCD Display W035U3248M-R 3.5 Inch Resistive Touch Uart LCD Display W035U3248-5-R 3.5 Inch Resistive Touch Uart LCD Display W035U3248M-5-R 3.5 Inch Resistive Touch Uart LCD Display W0371U2496-R 3.71 Inch Resistance Touch UART LCD Display W0371U2496M-R 3.71 Inch Resistance Touch UART LCD Display W043U4827-R 4.3 Inch Resistive Touch Uart LCD Display W043U4827M-R 4.3 Inch Resistive Touch Uart LCD Display W043U4827-5-R 4.3 Inch Resistive Touch Uart LCD Display W043U4827M-5-R 4.3 Inch Resistive Touch Uart LCD Display W043U8048-R 4.3 Inch Resistive Touch Uart LCD Display W043U8048M-R 4.3 Inch Resistive Touch Uart LCD Display W043U8048-5-R 4.3 Inch Resistive Touch Uart LCD Display W043U8048M-5-R 4.3 Inch Resistive Touch Uart LCD Display W070U8048-R 7.0 Inch Resistive Touch Uart LCD Display W070U8048M-R 7.0 Inch Resistive Touch Uart LCD Display W070U8048-5-R 7.0 Inch Resistive Touch Uart LCD Display W070U8048M-5-R 7.0 Inch Resistive Touch Uart LCD Display W070U1060-R 7.0 Inch Resistive Touch Uart LCD Display W070U1060M-R 7.0 Inch Resistive Touch Uart LCD Display W070U1060-5-R 7.0 Inch Resistive Touch Uart LCD Display W070U1060M-5-R 7.0 Inch Resistive Touch Uart LCD Display W101U1060-R 10.1 Inch Resistive Touch Uart LCD Display W101U1060M-R 10.1 Inch Resistive Touch Uart LCD Display W101U1060-5-R 10.1 Inch Resistive Touch Uart LCD Display W101U1060M-5-R 10.1 Inch Resistive Touch Uart LCD DisplayCapacitive Touch UART LCD DisplayW0154U2424-C 1.54 Inch Capacitance Touch UART LCD Display W0154U2424M-C 1.54 Inch Capacitance Touch UART LCD Display W024U2432-C 2.4 Inch Capacitance Touch UART LCD Display W024U2432M-C 2.4 Inch Capacitance Touch UART LCD Display W024U2432-5-C 2.4 Inch Capacitance Touch UART LCD Display W024U2432M-5-C 2.4 Inch Capacitance Touch UART LCD Display W028U2432-C 2.8 Inch Capacitive Touch Uart LCD Display W028U2432M-C 2.8 Inch Capacitive Touch Uart LCD Display W028U2432-5-C 2.8 Inch Capacitive Touch Uart LCD Display W028U2432M-5-C 2.8 Inch Capacitive Touch Uart LCD Display W032U2432-C 3.2 Inch Capacitive Touch Uart LCD Display W032U2432M-C 3.2 Inch Capacitive Touch Uart LCD Display W032U2432-5-C 3.2 Inch Capacitive Touch Uart LCD Display W032U2432M-5-C 3.2 Inch Capacitive Touch Uart LCD Display W035U3248-C 3.5 Inch Capacitive Touch Uart LCD Display W035U3248M-C 3.5 Inch Capacitive Touch Uart LCD Display W035U3248-5-C 3.5 Inch Capacitive Touch Uart LCD Display W035U3248M-5-C 3.5 Inch Capacitive Touch Uart LCD Display W0371U2496-C 3.71 Inch Capacitance Touch UART LCD Display W0371U2496M-C 3.71 Inch Capacitance Touch UART LCD Display W043U4827-C 4.3 Inch Capacitive Touch Uart LCD Display W043U4827M-C 4.3 Inch Capacitive Touch Uart LCD Display W043U4827-5-C 4.3 Inch Capacitive Touch Uart LCD Display W043U4827M-5-C 4.3 Inch Capacitive Touch Uart LCD Display W043U8048-C 4.3 Inch Capacitive Touch Uart LCD Display W043U8048M-C 4.3 Inch Capacitive Touch Uart LCD Display W043U8048-5-C 4.3 Inch Capacitive Touch Uart LCD Display W043U8048M-5-C 4.3 Inch Capacitive Touch Uart LCD Display W070U8048-C 7.0 Inch Capacitive Touch Uart LCD Display W070U8048M-C 7.0 Inch Capacitive Touch Uart LCD Display W070U8048-5-C 7.0 Inch Capacitive Touch Uart LCD Display W070U8048M-5-C 7.0 Inch Capacitive Touch Uart LCD Display W070U1060-C 7.0 Inch Capacitive Touch Uart LCD Display W070U1060M-C 7.0 Inch Capacitive Touch Uart LCD Display W070U1060-5-C 7.0 Inch Capacitive Touch Uart LCD Display W070U1060M-5-C 7.0 Inch Capacitive Touch Uart LCD Display W101U1060-C 10.1 Inch Capacitive Touch Uart LCD Display W101U1060M-C 10.1 Inch Capacitive Touch Uart LCD Display W101U1060-5-C 10.1 Inch Capacitive Touch Uart LCD Display W101U1060M-5-C W101U1060-5-C 10.1 Inch Capacitive Touch Uart LCD DisplayTN TFT LCD DisplayW0144P14S1SN-A02B0 1.44 Inch TN TFT LCD W0177P20S1CN-A02H0 1.77 Inch TN TFT LCD W0177P14S1SN-A02H0 1.77 Inch TN TFT LCD W020P36S2CN-A02B0 2.0 Inch TN TFT LCD W022P15S1SN 2.2 Inch TN TFT LCD W022P16S1CN-Y02H0 2.2 Inch TN TFT LCD W022P37S1CN-Y02H0 2.2 Inch TN TFT LCD W022P37S2CN-A02H0 2.2 Inch TN TFT LCD W024P18S1SN-A02B0 2.4 Inch TN TFT LCD W024P37S1CN-A02B0 2.4 Inch TN TFT LCD W024P40S1RN-A02B0 2.4 Inch TN TFT LCD W024P24S2MN 2.4 Inch TN TFT LCD W028P37S1CN-A02B0 2.8 Inch TN TFT LCD W028P40S1RN-A02B0 2.8 Inch TN TFT LCD W028P18S2SN-A02B0 2.8 Inch TN TFT LCD W028P45H1CN-A02B0 2.8 Inch TN TFT LCD W032P44S2RN-A02H0 3.2 Inch TN TFT LCD W032P40S1RN-A02B0 3.2 Inch TN TFT LCD W032P37S1SN-A02B0 3.2 Inch TN TFT LCD W032P18S1SN-A02B0 3.2 Inch TN TFT LCD W035P24S2MN-A02H0 3.5 Inch TN TFT LCD W035P54S1RN-H03I0 3.5 Inch TN TFT LCD W035P24S1MN-A02H0 3.5 Inch TN TFT LCD W043P40S1RN-Q52B0 4.3 Inch TN TFT LCD W050P40H2RN-Q53B0 5.0 Inch TN TFT LCD W050P40S1RN-Q53B0 5.0 Inch TN TFT LCD W070P39H5LI-J03B0 7.0 Inch TN TFT LCD W070P40S1RN-J03B0 7.0 Inch TN TFT LCD W070P50S3RN-J02B0 7.0 Inch TN TFT LCD W070P50S2RN-J03B0 7.0 Inch TN TFT LCD W070P50S1RN-J03B0 7.0 Inch TN TFT LCD W070P50S2RN-J05B0 7.0 Inch TN TFT LCD W070P50S1RN-J05B0 7.0 Inch TN TFT LCD W070P50S1RN-J05I0 7.0 Inch TN TFT LCD W070P50H5RN-J02B0 7.0 Inch TN TFT LCD W070P40H4LI-J03B0 7.0 Inch TN TFT LCD W080P40H1LN-J06B0 8.0 Inch TN TFT LCD W080P50S2RN-J06I0 8.0 Inch TN TFT LCD W080P50S4RN-J05I0 8.0 Inch TN TFT LCD W090P50S3RN-J05B0 9.0 Inch TN TFT LCD W090P50S3RN-J03B0 9.0 Inch TN TFT LCD W101P40H1LN-J05B0 10.1 Inch TN TFT LCD W101P40H2RN-J05B0 10.1 Inch TN TFT LCD W101P50H2RN-J05B0 10.1 Inch TN TFT LCD W104P40S1RN-K1B0 10.4 Inch TN TFT LCD W104C60E1LI-H16A0 10.4 Inch TN TFT LCD W156C30E1EI-J03B0 15.6 Inch TN TFT LCDIPS TFT LCD DisplayW101C30H1LI-J02B0 10.1 Inch IPS TFT LCD W101C31H1MI-J02B0 10.1 Inch IPS TFT LCD W101C31H2MI-J04B0 10.1 Inch IPS TFT LCD W101C40G1LI-S05B0 10.1 Inch IPS TFT LCD W101C40G1MI-S02B0 10.1 Inch IPS TFT LCD W101C40H1LI-J02B0 10.1 Inch IPS TFT LCD W101C40H1MI-J02B0 10.1 Inch IPS TFT LCD W101C40H2MI-J04B0 10.1 Inch IPS TFT LCD W101C40H3LI-J02B0 10.1 Inch IPS TFT LCD W101C40H3LI-J04B0 10.1 Inch IPS TFT LCD W0169P12S1SI 1.69 Inch IPS TFT LCD W0169P12S2SI 1.69 Inch IPS TFT LCD W020P12S1SI-A02B0 2.0 Inch IPS TFT LCD W020P30S1CI-A02B0 2.0 Inch IPS TFT LCD W020P24S1MI 2.0 Inch IPS TFT LCD W024P40S1RI-A02B0 2.4 Inch IPS TFT LCD W024P37S1CI-A02B0 2.4 Inch IPS TFT LCD W024P18S1SI-A02B0 2.4 Inch IPS TFT LCD W024P24S1MI 2.4 Inch IPS TFT LCD W028P40S1RI-A02B0 2.8 Inch IPS TFT LCD W028P18S2SI-A02B0 2.8 Inch IPS TFT LCD W028P37S1CI-A02B0 2.8 Inch IPS TFT LCD W030P40H1SI 3.0 Inch IPS TFT LCD W030P40H2RI 3.0 Inch IPS TFT LCD W030P12H1MI 3.0 Inch IPS TFT LCD W030P12H2RI 3.0 Inch IPS TFT LCD W035P40H1SI 3.5 Inch IPS TFT LCD W035P25H1MI 3.5 Inch IPS TFT LCD W035P60H1RI 3.5 Inch IPS TFT LCD W035P40S1RI-A02H0 3.5 Inch IPS TFT LCD W035P37S1RI-A02H0 3.5 Inch IPS TFT LCD W035P18S1SI-A02H03.5 Inch IPS TFT LCD W035P54S1RI-H03I0 3.5 Inch IPS TFT LCD W035P24S3MI-A02H0 3.5 Inch IPS TFT LCD W035P54S2RN-H03I0 3.5 Inch IPS TFT LCD W043P40H1RI-Q53B0 4.3 Inch IPS TFT LCD W043P40S1RI-Q53B0 4.3 Inch IPS TFT LCD W043P40H2MI-Z02B0 4.3 Inch IPS TFT LCD W050P24H1MI-S22B0 5.0 Inch IPS TFT LCD W050P24H2MI-S21B0 5.0 Inch IPS TFT LCD W050P40H2SI-S22B0 5.0 Inch IPS TFT LCD W050P40H1RI-Q53B0 5.0 Inch IPS TFT LCD W050P40H2RI-Q53B0 5.0 Inch IPS TFT LCD W050P24H3MI-S22B0 5.0 Inch IPS TFT LCD W055P25H4MI- S22B0 5.5 Inch IPS TFT LCD W055P25H1MI- S22B0 5.5 Inch IPS TFT LCD W055P31H1MI- S21B0 5.5 Inch IPS TFT LCD W055P30H1MI- S21B0 5.5 Inch IPS TFT LCD W055P25H3MI- S21B0 5.5 Inch IPS TFT LCD W055P25H5MI-S21B0 5.5 Inch IPS TFT LCD W070P40H3LI-J05B0 7.0 Inch IPS TFT LCD W070P40H1MI-J03B0 7.0 Inch IPS TFT LCD W070P40H1LI-J03B0 7.0 Inch IPS TFT LCD W070P40H1LI-J02B0 7.0 Inch IPS TFT LCD W070P40H6LI-J02B0 7.0 Inch IPS TFT LCD W070P50H1RI-J05B0 7.0 Inch IPS TFT LCD W070P50H1RI-J03B0 7.0 Inch IPS TFT LCD W070P50H1RI-J02B0 7.0 Inch IPS TFT LCD W070C40H1MI-J02B0 7.0 Inch IPS TFT LCD W070C31H1MI-J02B0 7.0 Inch IPS TFT LCD W070P50S3RI-J05B0 7.0 Inch IPS TFT LCD W070P30H1MI-J03B0 7.0 Inch IPS TFT LCD W070P40H2MI-J03B0 7.0 Inch IPS TFT LCD W070P40F1MI-Z02B0 7.0 Inch IPS TFT LCD W080C40H1MI-J02B0 8.0 Inch IPS TFT LCD W080C31H1MI-J02B0 8.0 Inch IPS TFT LCD W080C30H1MI-J02B0 8.0 Inch IPS TFT LCD W080P40H2LI-J06B0 8.0 Inch IPS TFT LCD W080C39H1MI-J03B0 8.0 Inch IPS TFT LCD W088B40Y3MI 8.8 Inch IPS TFT LCD W090P30H1MI-J05B0 9.0 Inch IPS TFT LCD W090P30H1MI-J03B0 9.0 Inch IPS TFT LCD W090P40H1LI-J05B0 9.0 Inch IPS TFT LCD W090P40H1LI-J03B0 9.0 Inch IPS TFT LCD W090P50H3RI-J05B0 9.0 Inch IPS TFT LCD W090P50H3RI-J03B0 9.0 Inch IPS TFT LCD W090C40H2MI-Z02B0 9.0 Inch IPS TFT LCD W101P40H1MI-J05B0 10.1 Inch IPS TFT LCD W101P31H1MI-J05B0 10.1 Inch IPS TFT LCD W101P30H1MI-J05B0 10.1 Inch IPS TFT LCD W101P40H1LI-J05B0 10.1 Inch IPS TFT LCD W101P40H4RI-J03B0 10.1 Inch IPS TFT LCD W101P40H3RI-J02B0 10.1 Inch IPS TFT LCD W101P40H1RI-J03B0 10.1 Inch IPS TFT LCD W101P50H2RI-J05B0 10.1 Inch IPS TFT LCD W101P40H2RI-J05B0 10.1 Inch IPS TFT LCD W101P50H3RI-J02B0 10.1 Inch IPS TFT LCD W101P50H1RI-J03B0 10.1 Inch IPS TFT LCD W116C30H1EI-J02B0 11.6 Inch IPS TFT LCD W121C40H2LI-Z07A0 12.1 Inch IPS TFT LCD W121C20E1LI-H19A0 12.1 Inch IPS TFT LCD W121C20E2LI-H18A0 12.1 Inch IPS TFT LCD W123C40H1LI-Z016I0 12.3 Inch IPS TFT LCD W133C30H2EI-J05B0 13.3 Inch IPS TFT LCD W133C30H1EI-J02B0 13.3 Inch IPS TFT LCD W150C20E1LI-H19A0 15.0 Inch IPS TFT LCD W156C30H1EI-J03B0 15.6 Inch IPS TFT LCD W170C30H1LI-Z010A0 17.0 Inch IPS TFT LCD W185C30H1LI-S012B0 18.5 Inch IPS TFT LCD W215C30H1LI-S011B0 21.5 Inch IPS TFT LCD W238C30H2LI-S08B0 23.8 Inch IPS TFT LCD W270C30H1LI-S09B0 27 Inch IPS TFT LCDSunlight Readable DisplaysW035P54S2RN-H03I0 3.5 Inch Sunlight Readable LCD Display W035P54S1RN-H03I0 3.5 Inch Sunlight Readable LCD Display W035P54S1RI-H03I0 3.5 Inch Sunlight Readable LCD Display W035P24S3MI-A02H0 3.5 Inch Sunlight Readable LCD Display W035P18S1SI-A02H0 3.5 Inch Sunlight Readable LCD Display W035P37S1RI-A02H0 3.5 Inch Sunlight Readable LCD Display W035P40S1RI-A02H0 3.5 Inch Sunlight Readable LCD Display W043P40H2MI-Z02B0 4.3 Inch Sunlight Readable LCD Display W043P40S1RN-Q52B0 4.3 Inch Sunlight Readable LCD Display W043P40S1RI-Q53B0 4.3 Inch Sunlight Readable LCD Display W043P40H1RI-Q53B0 4.3 Inch Sunlight Readable LCD Display W050P40H2RI-Q53B0 5 Inch Sunlight Readable LCD Display W050P40H1RI-Q53B0 5 Inch Sunlight Readable LCD Display W070P40F1MI-Z02B0 7 Inch Sunlight Readable LCD Display W070P40S1RN-J03B0 7 Inch Sunlight Readable LCD Display W070P50S3RN-J02B0 7 Inch Sunlight Readable LCD Display W070P50S2RN-J03B0 7 Inch Sunlight Readable LCD Display W070P50S2RN-J05B0 7 Inch Sunlight Readable LCD Display W070P50S1RN-J03B0 7 Inch Sunlight Readable LCD Display W070P50S1RN-J05B0 7 Inch Sunlight Readable LCD Display W070P50S1RN-J05I0 7 Inch Sunlight Readable LCD Display W070P50H5RN-J02B0 7 Inch Sunlight Readable LCD Display W070P40H4LI-J03B0 7 Inch Sunlight Readable LCD Display W070P39H5LI-J03B0 7 Inch Sunlight Readable LCD Display W070P50S3RI-J05B0 7 Inch Sunlight Readable LCD Display W070P50H1RI-J02B0 7 Inch Sunlight Readable LCD Display W070P50H1RI-J03B0 7 Inch Sunlight Readable LCD Display W070P50H1RI-J05B0 7 Inch Sunlight Readable LCD Display W070P40H6LI-J02B0 7 Inch Sunlight Readable LCD Display W070P40H1LI-J02B0 7 Inch Sunlight Readable LCD Display W070P40H1LI-J03B0 7 Inch Sunlight Readable LCD Display W070P40H3LI-J05B0 7 Inch Sunlight Readable LCD Display W070P40H1MI-J03B0 7 Inch Sunlight Readable LCD Display W070P40H2MI-J03B0 7 Inch Sunlight Readable LCD Display W070P30H1MI-J03B0 7 Inch Sunlight Readable LCD Display W070C31H1MI-J02B0 7 Inch Sunlight Readable LCD Display W070C40H1MI-J02B0 7 Inch Sunlight Readable LCD Display W080C39H1MI-J03B0 8 Inch Sunlight Readable LCD Display W080P40H1LN-J06B0 8 Inch Sunlight Readable LCD Display W080P50S2RN-J06I0 8 Inch Sunlight Readable LCD Display W080C30H1MI-J02B0 8 Inch Sunlight Readable LCD Display W080C31H1MI-J02B0 8 Inch Sunlight Readable LCD Display W080C40H1MI-J02B0 8 Inch Sunlight Readable LCD Display W101C40F2MI-J04B0 10.1 Inch Sunlight Readable LCD Display W101P40H2RN-J05B0 10.1 Inch Sunlight Readable LCD Display W101P50H2RN-J05B0 10.1 Inch Sunlight Readable LCD Display W101P40H1LN-J05B0 10.1 Inch Sunlight Readable LCD Display W101P50H1RI-J03B0 10.1 Inch Sunlight Readable LCD Display W101P50H3RI-J02B0 10.1 Inch Sunlight Readable LCD Display W101P40H2RI-J05B0 10.1 Inch Sunlight Readable LCD Display W101P50H2RI-J05B0 10.1 Inch Sunlight Readable LCD Display W101P40H1RI-J03B0 10.1 Inch Sunlight Readable LCD Display W101P40H3RI-J02B0 10.1 Inch Sunlight Readable LCD Display W101P40H4RI-J03B0 10.1 Inch Sunlight Readable LCD Display W101P40H1LI-J05B0 10.1 Inch Sunlight Readable LCD Display W101P30H1MI-J05B0 10.1 Inch Sunlight Readable LCD Display W101P31H1MI-J05B0 10.1 Inch Sunlight Readable LCD Display W101P40H1MI-J05B0 10.1 Inch Sunlight Readable LCD Display W101C30F1LI-J02B0 10.1 Inch Sunlight Readable LCD Display W101C40F1LI-J02B0 10.1 Inch Sunlight Readable LCD Display W101C40F3LI-J02B0 10.1 Inch Sunlight Readable LCD Display W101C40F3LI-J04B0 10.1 Inch Sunlight Readable LCD Display W101C31F1MI-J02B0 10.1 Inch Sunlight Readable LCD Display W101C31F2MI-J04B0 10.1 Inch Sunlight Readable LCD Display W101C40F1MI-J02B0 10.1 Inch Sunlight Readable LCD DisplayBar TFT LCD DisplayW0096B13S1SI 0.96 Inch Bar Tft LCD W019B16S1SI-X01B0 1.9 Inch Bar Tft LCD W019B30S1CI-X01B0 1.9 Inch Bar Tft LCD W024B40S1RI-H02B0 2.4 Inch Bar Tft LCD W0316B40H1MI 3.16 Inch Bar Tft LCD W0316B40H1RI 3.16 Inch Bar Tft LCD W037B30H1MI 3.71 Inch Bar Tft LCD W037B45H1RI 3.71 Inch Bar Tft LCD W040B30H1MI 3.99 Inch Bar Tft LCD W040B40H1RI 3.99 Inch Bar Tft LCD W0458B40H3RI 4.58 Inch Bar Tft LCD W0458B30H3MI 4.58 Inch Bar Tft LCD W068B40H6MI 6.86 Inch Bar Tft LCD W0150B10S1SI 1.5 Inch Bar TFT LCD Display W0147B12S1SI 1.47 Inch Bar TFT LCD Display W030B12H7MI 3 Inch Bar TFT LCD Display W030B12H8MI 3 Inch Bar TFT LCD Display W035B30H1MI 3.5 Inch Bar TFT LCD Display W035B40H1RI 3.5 Inch Bar TFT LCD Display W067B40H1RI 6.75 Inch Bar TFT LCD Display W067B30H1MI 6.75 Inch Bar TFT LCD Display W070B40Z1RI-Z03B0 7 Inch Bar TFT LCD Display W078B40Z3RI-Z04B0 7.84 Inch Bar TFT LCD Display W104P40S1RN-K1B0 10.4 Inch Bar TFT LCD Display W123C40H1LI-Z016I0 12.3 Inch Bar TFT LCD DisplayCircular TFT LCD DisplayW0160R16H1SI-X01B0 1.6 Inch Circular TFT LCD W0160R20H1MI-X01B0 1.6 Inch Circular TFT LCD W018R40S1RI-X02B0 1.8 Inch Circular TFT LCD W018R20S1RMI-X02B0 1.8 Inch Circular TFT LCD W021R30S1MI 2.1 Inch Circular TFT LCD W021R40S2RI 2.1 Inch Circular TFT LCD W0276R30S1MI-H02B0 2.76 Inch Circular TFT LCD W0276R40S1RI-H02B0 2.76 Inch Circular TFT LCD W034R40S1RI-H02B0 3.4 Inch Circular TFT LCD W036R30H1LI-X02B0 3.6 Inch Circular TFT LCD W040R40H2RI-X02B0 4.0 Inch Circular TFT LCD W040R30H2MI-X02B0 4.0 Inch Circular TFT LCD W050R50H1MI 5.0 Inch Circular TFT LCD W0090R24S2SI 0.9 Inch Round TFT LCD W0128R15S1CI 1.28 Inch Round LCD W0132R15S3SI 1.32 Inch Round TFT LCD W0146R18S1SI 1.46 Inch Round TFT LCDSquare TFT LCD DisplayW0251S15S1SN-X02B0 2.51 Inch Square TFT LCD W034S40S1SI 3.4 Inch Square TFT LCD W034S20S3MI 3.4 Inch Square TFT LCD W0130S24S1CI 1.3 Inch Square TFT LCD Display W0130S13S2SI 1.3 Inch Square TFT LCD Display W0144S14S1SN-A02B0 1.44 Inch Square TFT LCD Display W0154S22S1CI 1.54 Inch Square TFT LCD Display W0154S16S1MI 1.54 Inch Square TFT LCD Display W0395S30H1MI-H02B0 3.95 Inch Square TFT LCD Display W0395S40S1RI-H02B0 3.95 Inch Square TFT LCD Display W0395S40S1MI-H02B0 3.95 Inch Square TFT LCD Display W0395S40H1RI-H02B0 3.95 Inch Square TFT LCD Display W076S30H1MI-H05B0 MI 7.6 Inch Square TFT LCD DisplayRaspberry Pi LCD DisplayMPI2411 2.4 Inch Raspberry Pi LCD MPI2801 2.8 Inch Raspberry Pi LCD MPI3201 3.2 Inch Raspberry Pi LCD MPI3508 3.5 Inch Raspberry Pi LCD MPI4008 4.0 Inch Raspberry Pi LCD MPI4305 4.3 Inch Raspberry Pi LCD MPI5008 5.0 Inch Raspberry Pi LCD MPI5001 5 Inch Raspberry Pi HDMI LCD Display(CTP) MPI5518 5.5 Inch Raspberry Pi HDMI LCD Display MPI7001 7.0 Inch Raspberry Pi LCD MPI8008 8 Inch Raspberry Pi HDMI LCD Display MPI1001 10.1 Inch Raspberry Pi LCD MPI2418 2.4 Raspberry Pi GPIO Display MPI3501 3.5 Raspberry Pi GPIO Display MPI1008 10.1 Raspberry Pi HDMI LCD Display MPI1009 10.1 Raspberry Pi HDMI LCD Display(CTP) MPI7002 7 Raspberry Pi HDMI LCD Display MPI7006 7 Raspberry Pi HDMI LCD Display(speaker-CTP) MPI7008 7 Raspberry Pi HDMI LCD Display(Earphone-CTP) MHS3528 3.5 Raspberry Pi MHS LCD Display MHS4001 4 Raspberry Pi MHS LCD Display MHS3232 3.2 Raspberry Pi MHS LCD DisplayRGB Display ModuleMRG4301 4.3 Inch RGB Display Module MRG5111 5.0 Inch RGB Display Module MRG7122 7.0 Inch RGB Display Module MRG4311 4.3 Inch RGB Display Module(CTP) MRG5101 5.0 Inch RGB Display Module(NC) MRG7101 7.0 Inch RGB Display Module(TN-NC) MRG7102 7.0 Inch RGB Display Module(IPS-NC) MRG7111 7.0 Inch RGB Display Module(TN-CTP)SPI Disaply LCD ModuleMSP0962 0.96 Inch SPI Disaply LCD Module MSP1141 1.14 Inch SPI Disaply LCD Module MSP1281 1.28 Inch SPI Disaply LCD Module MSP1308 1.3 Inch SPI Disaply LCD Module MSP1443 1.44 Inch SPI Disaply LCD Module MSP1541 1.54 Inch SPI Disaply LCD Module MSP1601 1.6 Inch SPI Disaply LCD Module MSP1803 1.8 Inch SPI Disaply LCD Module MA R2001 2.0 Inch SPI Disaply LCD Module MSP2202 2.2 Inch SPI Disaply LCD Module MSP2402 2.4 Inch SPI Disaply LCD Module MSP2807 2.8 Inch SPI Disaply LCD Module MSP3208 3.2 Inch SPI Disaply LCD Module MSP3526 3.5 Inch SPI Disaply LCD Module MSP4022 4.0 Inch SPI Disaply LCD Module MSP0961 0.96 Inch SPI Disaply LCD Module (NC/RTP) MSP0964 0.96Inch SPI Disaply LCD Module MSP1804 1.8 Inch SPI Disaply LCD Module MSP1805 1.8 Inch SPI Disaply LCD Module MSP2833 2.8 Inch SPI Disaply LCD Module(CTP) MSP3222 3.2 Inch SPI Disaply LCD Module(CTP) MSP3520 3.5 Inch SPI Disaply LCD Module MSP4030 4.0 Inch SPI Disaply LCD Module(CTP) MAR1441 1.44 SPI LCD Disaply Module MAR1801 1.8 SPI LCD Disaply Module MAR2001 2.0 Inch SPI LCD Disaply Module MAR2201 2.2 Inch SPI LCD Disaply ModuleParallel-Port Display ModuleMRB2408 2.4 Inch Parallel-Port Display Module MRB2801 2.8 Inch Parallel-Port Display Module MRB3205 3.2 Inch Parallel-Port Display Module MRB3503 3.5 Inch Parallel-Port Display Module MRB3973 3.97 Inch Parallel-Port Display Module MRB3951 4.0 Inch Parallel-Port Display Module MRB3511 3.5 Inch Parallel-Port Display Module(CTP) MRB3512 3.5 Inch Parallel-Port Display ModuleResistive Touch ScreenRXA-024017-01 2.4 Inch Resistive Touch Screen RXA-024034-01 2.4 Inch Resistive Touch Screen RXA-028022-05 2.8 Inch Resistive Touch Screen RXA-028004-03 2.8 Inch Resistive Touch Screen RXA-028012-03 2.8 Inch Resistive Touch Screen RXA-032009-01 3.2 Inch Resistive Touch Screen RXA-032011-03 3.2 Inch Resistive Touch Screen RXA-035072-02 3.5 Inch Resistive Touch Screen RXA-035004 3.5 Inch Resistive Touch Screen RXA-035025-09 3.5 Inch Resistive Touch Screen RXA-035028-01 3.5 Inch Resistive Touch Screen RXA-035043-02 3.5 Inch Resistive Touch Screen RXA-035069-01 3.5 Inch Resistive Touch Screen RXA-043009-05 4.3 Inch Resistive Touch Screen RXA-043001-01 4.3 Inch Resistive Touch Screen RXA-043001-18 4.3 Inch Resistive Touch Screen RXA-043001-34 4.3 Inch Resistive Touch Screen RXA-043002-01 4.3 Inch Resistive Touch Screen RXA-043005-01 4.3 Inch Resistive Touch Screen RXA-043005-04 4.3 Inch Resistive Touch Screen RXA-043005-09 4.3 Inch Resistive Touch Screen RAX-050001-02 5.0 Inch Resistive Touch Screen RXA-050001-08 5.0 Inch Resistive Touch Screen RXA-050002-01 5.0 Inch Resistive Touch Screen RXA-050002-04 5.0 Inch Resistive Touch Screen RXA-050003-01 5.0 Inch Resistive Touch Screen RXA-050003-08 5.0 Inch Resistive Touch Screen RXA-050004-01 5.0 Inch Resistive Touch Screen RXA-050004-08 5.0 Inch Resistive Touch Screen RXA-057009-02 5.7 Inch Resistive Touch Screen RXA-057002-01 5.7 Inch Resistive Touch Screen RXA-070043-01 7.0 Inch Resistive Touch Screen RXA-070001-01 7.0 Inch Resistive Touch Screen RXA-070003-01 7.0 Inch Resistive Touch Screen RXA-070007-01 7.0 Inch Resistive Touch Screen RXA-070007-11 7.0 Inch Resistive Touch Screen RXA-070010-01 7.0 Inch Resistive Touch Screen RXA-070017-02 7.0 Inch Resistive Touch Screen RXA-070029-06 7.0 Inch Resistive Touch Screen RXA-070036-02 7.0 Inch Resistive Touch Screen RXA-070037-03 7.0 Inch Resistive Touch Screen RXA-080011-R02A 8.0 Inch Resistive Touch Screen RXA-080026-01 8.0 Inch Resistive Touch Screen TSA-080021-07 8.0 Inch Resistive Touch Screen RXA-080.E 8.0 Inch Resistive Touch Screen TSA-090008-01 9.0 Inch Resistive Touch Screen RXA-090005-02 9.0 Inch Resistive Touch Screen RXA-101042-01 10.1 Inch Resistive Touch Screen RXA-101001-03 10.1 Inch Resistive Touch Screen RXA-101002-01 10.1 Inch Resistive Touch Screen RXA-101006-01 10.1 Inch Resistive Touch Screen RXA-101013-01 10.1 Inch Resistive Touch Screen RXA-101027-01 10.1 Inch Resistive Touch Screen RXA-101028-01 10.1 Inch Resistive Touch Screen RXA-104018-01 10.4 Inch Resistive Touch Screen RXA-104001-01 10.4 Inch Resistive Touch Screen RXA-104013-01 10.4 Inch Resistive Touch Screen RXA-150010-01 15.0 Inch Resistive Touch Screen RXF-17003-01 17.0 Inch Resistive Touch Screen RXF-190001-01 19.0 Inch Resistive Touch ScreenCapacitive Touch ScreenRXC-GG035081A-1.0 3.5 Inch Capacitive Touch Screen RXC-GG03501F-1.0 3.5 Inch Capacitive Touch Screen RXC-PG03501-01 3.5 Inch Capacitive Touch Screen RXC-PG04302C-1.0 4.3 Inch Capacitive Touch Screen RXC-GG050326A-2.0 5.0 Inch Capacitive Touch Screen RXC-GG05023C-1.0 5.0 Inch Capacitive Touch Screen RXC-GG05022-01 5.0 Inch Capacitive Touch Screen RXC-GG050233A-1.0 5.0 Inch Capacitive Touch Screen RXC-GG05004-01 5.0 Inch Capacitive Touch Screen RXC-PG05002-01 5.0 Inch Capacitive Touch Screen RXC-PG050003-01 5.0 Inch Capacitive Touch Screen RXC-GG07012-01 7.0 Inch Capacitive Touch Screen RXC-PG07019-01 7.0 Inch Capacitive Touch Screen RXC-PG07038A-1.0 7.0 Inch Capacitive Touch Screen RXC-GG07028C-1.0 7.0 Inch Capacitive Touch Screen RXC-GG070122E-1.0 7.0 Inch Capacitive Touch Screen RXC-PG070089C-1.0 7.0 Inch Capacitive Touch Screen RXC-GG070089D-1.0 7.0 Inch Capacitive Touch Screen RXC-GG070122A-1.0 7.0 Inch Capacitive Touch Screen RXC-GG070089A-1.0 7.0 Inch Capacitive Touch Screen RXC-GG070136A-1.0 7.0 Inch Capacitive Touch Screen RXC-GG070180A-1.0 7.0 Inch Capacitive Touch Screen RXC-GG070324A-1.0 7.0 Inch Capacitive Touch Screen RXC-GG070324B-1.0 7.0 Inch Capacitive Touch Screen RXC-PG070187A-1.0 7.0 Inch Capacitive Touch Screen RXC-GG07020B-2.0 7.0 Inch Capacitive Touch Screen RXC-PG080093C-1.0 8.0 Inch Capacitive Touch Screen RXC-GG080276A-1.0 8.0 Inch Capacitive Touch Screen RXC-PG080078A-1.0 8.0 Inch Capacitive Touch Screen RXC-PG080134A-1.0 8.0 Inch Capacitive Touch Screen RXC-GG08002D-1.0 8.0 Inch Capacitive Touch Screen RXC-GG08093F-1.0 8.0 Inch Capacitive Touch Screen RXC-GG10036G-1.0 10.1 Inch Capacitive Touch Screen RXC-PG101252A-1.0 10.1 Inch Capacitive Touch Screen RXC-PG101240A-1.0 10.1 Inch Capacitive Touch Screen RXC-PG10105B-1.0 10.1 Inch Capacitive Touch Screen RXC-PG10104-01 10.1 Inch Capacitive Touch Screen RXC-GG101240E-1.0 10.1 Inch Capacitive Touch Screen RXC-GG101135A-1.0 10.1 Inch Capacitive Touch Screen RXC-GG101080A-1.0 10.1 Inch Capacitive Touch Screen RXC-GG101068A-1.0 10.1 Inch Capacitive Touch Screen GGY18.5A-1.0 18.5 Inch Capacitive Touch Screen RXC-GG320094A-1.0 32 Inch Capacitive Touch ScreenINNOLUX LCD PanelLQ35NC111 3.5 Inch INNOLUX LCD Panel AT043TN24 V.7 4.3 Inch INNOLUX LCD Panel AT043TN25 V.2 4.3 Inch INNOLUX LCD Panel EJ050NA-01G 5.0 Inch INNOLUX LCD Panel ZJ050NA-08C 5.0 Inch INNOLUX LCD Panel AT056TN53 V.1 5.6 Inch INNOLUX LCD Panel G057VCE-TH1 5.7 Inch INNOLUX LCD Panel AT065TN14 6.5 Inch INNOLUX LCD Panel LW700AT9309 7.0 Inch INNOLUX LCD Panel AT070TN83 V.1 7.0 Inch INNOLUX LCD Panel AT070TN92 7.0 Inch INNOLUX LCD Panel AT070TN94 7.0 Inch INNOLUX LCD Panel G070Y2-L01 7.0 Inch INNOLUX LCD Panel G070ACE-L01 7.0 Inch INNOLUX LCD Panel G070ACE-LH1 7.0 Inch INNOLUX LCD Panel G070ACE-LH2 7.0 Inch INNOLUX LCD Panel G070ACE-LH3 7.0 Inch INNOLUX LCD Panel NJ070NA-23A 7.0 Inch INNOLUX LCD Panel AT080TN64 8.0 Inch INNOLUX LCD Panel EJ080NA-05B 8.0 Inch INNOLUX LCD Panel ZJ080NA-08A 8.0 Inch INNOLUX LCD Panel EJ080NA-04C 8.0 Inch INNOLUX LCD Panel DJ080IA-11A 8.0 Inch INNOLUX LCD Panel AT090TN12 V.3 9.0 Inch INNOLUX LCD Panel EJ101IA-01G 10.1 Inch INNOLUX LCD Panel G101ICE-LH1 10.1 Inch INNOLUX LCD Panel NJ101IA-01S 10.1 Inch INNOLUX LCD Panel AT102TN03 V.8 10.2 Inch INNOLUX LCD Panel AT102TN03 V.9 10.2 Inch INNOLUX LCD Panel G104XCE-LH1 10.4 Inch INNOLUX LCD Panel G104V1-T03 10.4 Inch INNOLUX LCD Panel G104X1-L04 10.4 Inch INNOLUX LCD Panel G104XCE-LM1 10.4 Inch INNOLUX LCD Panel G104AGE-L02 10.4 Inch INNOLUX LCD Panel G104ACJ-L01 10.4 Inch INNOLUX LCD Panel G104XCE-L01 10.4 Inch INNOLUX LCD Panel G104ACE-LH1 10.4 Inch INNOLUX LCD Panel G121XCE-L01 12.1 Inch INNOLUX LCD Panel G121XCE-L02 12.1 Inch INNOLUX LCD Panel G121ACE-LH1 12.1 Inch INNOLUX LCD Panel G121ACE-LH2 12.1 Inch INNOLUX LCD Panel G121ICE-L01 12.1 Inch INNOLUX LCD Panel G150XJE-E01 15.0 Inch INNOLUX LCD Panel G150XNE-L02 15.0 Inch INNOLUX LCD Panel G150XNE-L03 15.0 Inch INNOLUX LCD Panel G150XGE-L04 15.0 Inch INNOLUX LCD Panel G150XNE-L01 15.0 Inch INNOLUX LCD Panel G156HCE-L01 15.6 Inch INNOLUX LCD Panel G156HCE-LN1 15.6 Inch INNOLUX LCD Panel G156HCE-LH1 15.6 Inch INNOLUX LCD Panel G156BGE-L01 15.6 Inch INNOLUX LCD Panel G156BGE-L03 15.6 Inch INNOLUX LCD Panel G156HCE-E01 15.6 Inch INNOLUX LCD Panel G185BGE-L01 18.5 Inch INNOLUX LCD Panel G200HJJ-L01 19.5 Inch INNOLUX LCD Panel R213UCE-L01 21.3 Inch INNOLUX LCD Panel R213UCE-L02 21.3 Inch INNOLUX LCD Panel M236HJJ-L31 23.6 Inch INNOLUX LCD Panel G238HCJ-L01 23.8 Inch INNOLUX LCD Panel G238HCJ-LH1 23.8 Inch INNOLUX LCD PanelAUO LCD PanelG043FTN01.0 4.3 AUO LCD Panel G043FTT01.0 4.3 AUO LCD Panel G050VTN01.1 5.0 AUO LCD Panel G057QN01 V2 5.7 AUO LCD Panel G057VN01 V2 5.7 AUO LCD Panel G065VN01 V2 6.5 AUO LCD Panel G065VN01 V221 6.5 AUO LCD Panel A070VTN06.4 7.0 AUO LCD Panel A070VW08 V2 7.0 AUO LCD Panel A070VTN06.1 7.0 AUO LCD Panel G070VTN02.0 7.0 AUO LCD Panel C070VW02 V1 7.0 AUO LCD Panel G070VW01 V0 7.0 AUO LCD Panel G070VVN01.2 7.0 AUO LCD Panel G070VTN01.0 7.0 AUO LCD Panel A080STN01.0 8.0 AUO LCD Panel C080EAN04.3 8.0 AUO LCD Panel G080UAN01.0 8.0 AUO LCD Panel G080UAN02.2 8.0 AUO LCD Panel G084SN05 V9 8.4 AUO LCD Panel G084XAN01.0 8.4 AUO LCD Panel A101VW01 V3 10.1 AUO LCD Panel G101STN01.C 10.1 AUO LCD Panel G101EAN02.4 10.1 AUO LCD Panel G101EAN01.0 10.1 AUO LCD Panel G104XVN01.0 10.4 AUO LCD Panel G104SN03V5 10.4 AUO LCD Panel G104VN01 V1 10.4 AUO LCD Panel G104STN01.0 10.4 AUO LCD Panel G121STN02.0 12.1 AUO LCD Panel G121XN01 V0 12.1 AUO LCD Panel G121EAN01.4 12.1 AUO LCD Panel C123HAN02.5 12.3 AUO LCD Panel C123HAN06.0 12.3 AUO LCD Panel C123HAX02.2 12.3 AUO LCD Panel G133HAN01.1 13.3 AUO LCD Panel G133XTN01.0 13.3 AUO LCD Panel G150XTN06.0 15.0 AUO LCD Panel G156XTN01.0 15.6 AUO LCD Panel G156HAN04.0 15.6 AUO LCD Panel G170EG01 V1 17.0 AUO LCD Panel G170HAN01.1 17.0 AUO LCD Panel G173HW01 V0 17.3 AUO LCD Panel G185HAN01.0 18.5 AUO LCD PanelTianma LCD PanelTM035KDH03-79 3.5 Tianma LCD Panel TM043NDHG11 4.3 Tianma LCD Panel TM050RDH03-41 5.0 Tianma LCD Panel TM050RDZG03-00 5.0 Tianma LCD Panel TM057KDH01-00 5.7 Tianma LCD Panel P0650VGF1MA00 6.5 Tianma LCD Panel P0650VGF1MA10 6.5 Tianma LCD Panel TM070JDHG34-00 7.0 Tianma LCD Panel TM070RDHG34-00 7.0 Tianma LCD Panel P0800WVF1MA00 8.0 Tianma LCD Panel TM080TDHG01-00 8.0 Tianma LCD Panel P0840XGF1MA00 8.4 Tianma LCD Panel TM101DDHG01-00 10.1 Tianma LCD Panel TM101JDHG30-00 10.1 Tianma LCD Panel TM101JDHP01-00 10.1 Tianma LCD Panel P1040XGF1MA00 10.4 Tianma LCD Panel P1210XGF1MA00 12.1 Tianma LCD Panel TM121TDSG02-00 12.1 Tianma LCD Panel TM123XDHP90-00 12.3 Tianma LCD Panel TM150TDSG71 15.1 Tianma LCD PanelRGB TTL LCD Controller BoardPCB800099-V.9 RGB TTL LCD Controller Board PCB800168 RGB TTL LCD Controller Board PCB800827 RGB TTL LCD Controller Board PCB800850 RGB TTL LCD Controller Board PCB800851 RGB TTL LCD Controller Board PCB800852 RGB TTL LCD Controller Board PCB800872 RGB TTL LCD Controller Board PCB800882 RGB TTL LCD Controller Board PCB800883 RGB TTL LCD Controller Board SD070-706-V.3 RGB TTL LCD Controller Board UT-MD07080 V.3 RGB TTL LCD Controller Board UT-706-035 RGB TTL LCD Controller Board UT-2660 RGB TTL LCD Controller Board UT-HDMI035 RGB TTL LCD Controller Board UT-MD043050 V.2 RGB TTL LCD Controller Board UT-MD070201 V.1 RGB TTL LCD Controller Board UT-TCON-035 RGB TTL LCD Controller Board UT-LVDS-5 RGB TTL LCD Controller Board UT-TCON-N1.1 RGB TTL LCD Controller BoardLVDS LCD Controller BoardPCB800853 LVDS LCD Controller Board PCB800885 LVDS LCD Controller Board PCB800812 LVDS LCD Controller Board PCB800815 LVDS LCD Controller Board PCB800661 V.9 LVDS LCD Controller Board PCB800809 LVDS LCD Controller Board PCB800810 LVDS LCD Controller Board PCB800823 LVDS LCD Controller Board UT-2556 V.2 LVDS LCD Controller Board UT-2660 V.1 LVDS LCD Controller Board ND-R60H LVDS LCD Controller Board M.NT68676.3 LVDS LCD Controller Board JRY-W9KFHD-EV1 LVDS LCD Controller Board WH-RTD3513-V7 LVDS LCD Controller Board WH-A40I LVDS LCD Controller Board UT-101G LVDS LCD Controller BoardPortable Display MonitorM116H1PTMI 11.6 Inch Portable Monitor M116H2PTMI 11.6 Inch Portable Monitor M116H1MI 11.6 Inch Portable Monitor M133H1PTMI-4K 13.3 Inch Portable Monitor M133H1PTMI-2K 13.3 Inch Portable Monitor M133H1PTMI 13.3 Inch Portable Monitor M133H1MI 13.3 Inch Portable Monitor M140H1MI 14.0 Inch Portable Monitor M140H1PTMI 14.0 Inch Portable Monitor M140H1PTMI-2K 14.0 Inch Portable Monitor M156H1PTMI-2K 15.6 Inch Portable Monitor M156H1PTMI 15.6 Inch Portable Monitor M156H1MI 15.6 Inch Portable Monitor M160H1PTMI-2.5K 16.0 Inch Portable Monitor M173H1PTMI-2k 17.3 Inch Portable Monitor M173H1PTMI 17.3 Inch Portable Monitor M185H1PTMI 18.5 Inch Portable MonitorStandard Display MonitorM043S01-A 4.3 Inch LCD Monitor M043S01-Fold 4.3 Inch LCD Monitor M050S01-A 5 Inch LCD Monitor M070S01-E 7 Inch LCD Monitor M070S01-V 7 Inch LCD Monitor M070S01-VHP 7 Inch LCD Monitor M101H01-V 10.1 Inch LCD Monitor M101H01-VP 10.1 Inch LCD Monitor M116H02EI-E 11.6 Inch LCD Monitor M116H02EI-H 11.6 Inch LCD Monitor M56H01ZP 15.6 Inch LCD Monitor M156H01-VP 15.6 Inch LCD Monitor M185H01P-H 18.5 Inch LCD Monitor M185H01P 18.5 Inch LCD Monitor M215H01P 21.5 Inch LCD Monitor M215H01P 21.5 Inch IPS LCD Monitor M238H01P 23.8 Inch LCD Monitor M270H01P 27.0 Inch LCD Monitor

- Solutions

- Blog

- Resources

- Company

- Services

- Contact

English

English